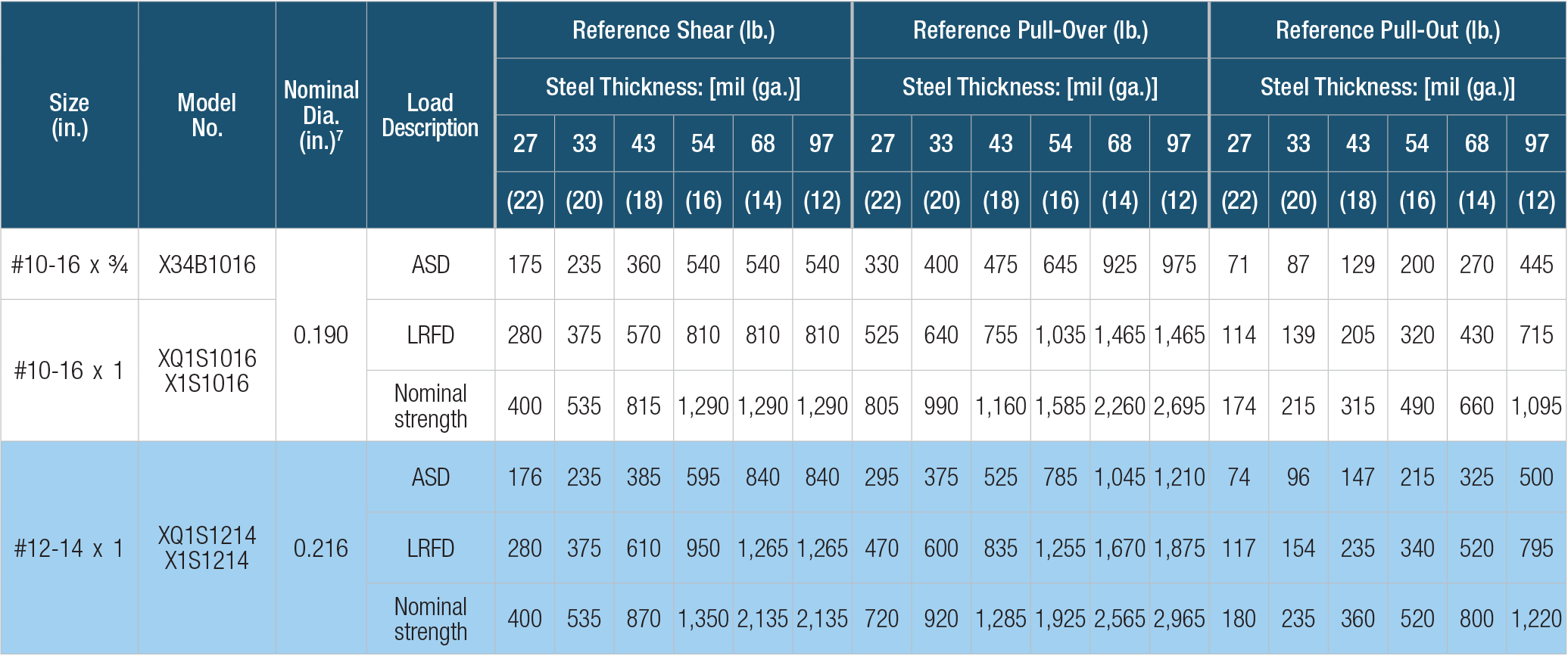

Allowable loads are based on simpson strong tie laboratory testing with a safety factor of 5 0 applied to the average ultimate test load.

Allowable gap between two steel sheets connected with screws.

However the presence of a separation may impact the tilting tearing connection capacity and the screw strength.

The ultimate shear value load of single lap connection was noted.

Minimum heel heights required for full table loads are based on a minimum 2 12 pitch.

The connections were subjected to forces parallel to the plane of interconnection.

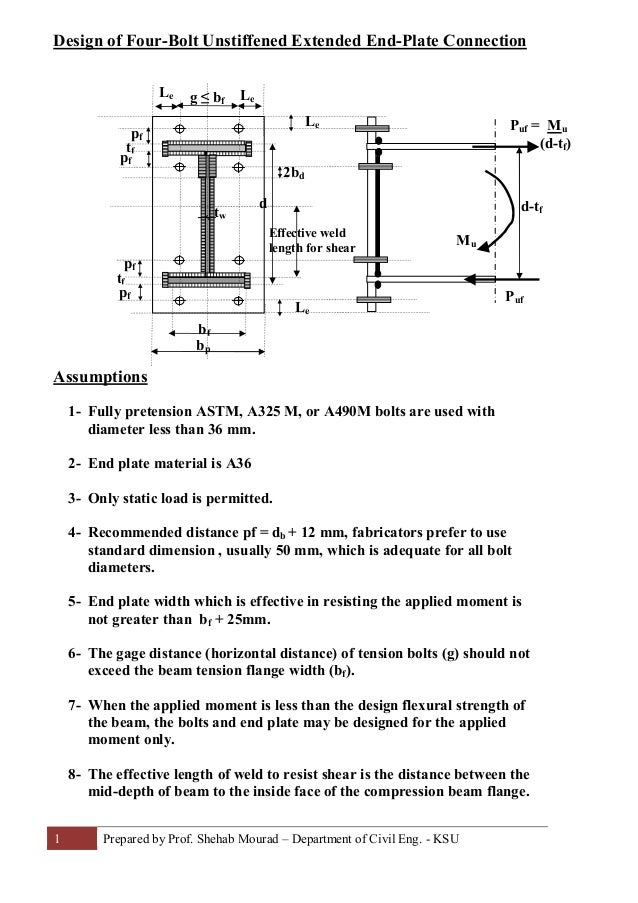

Determine the number of 3 in long in diameter lag screws needed to connect a in.

The maximum hanger gap is measured between the joist or truss end and the carrying member.

The presence of a gap or separation of the steel sheets would likely have little effect on the bearing capacity of a screw connection.

Final allowable load for a connection.

Sds heavy duty connector screw cont 1.

Allowable loads are shown at the wood load duration factor of.

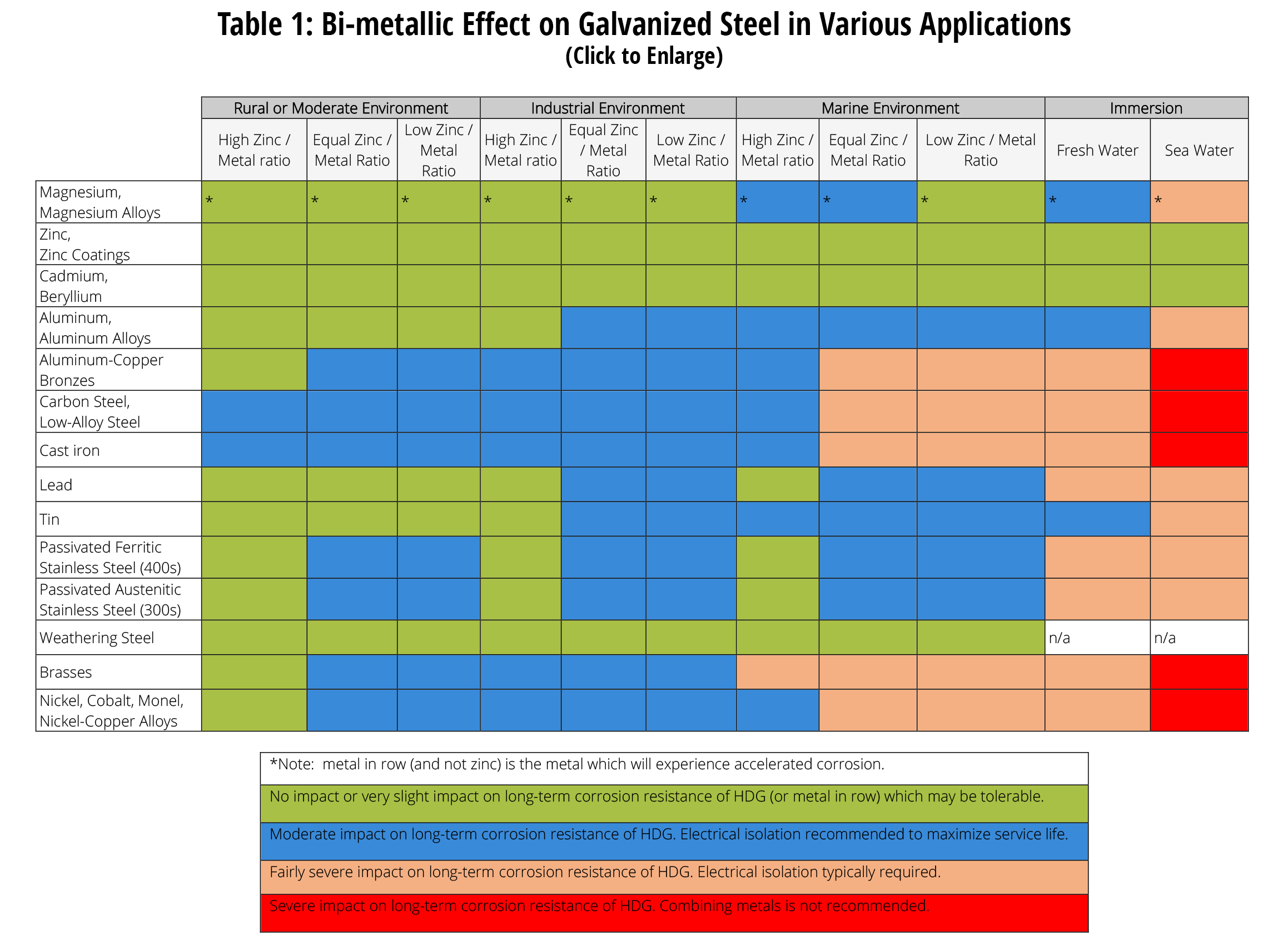

Engineers are often surprised to see a 40 50 even 60 drop in.

Both lateral single and double shear and withdrawal capacities can be determined.

With a gap of zero g 0 the tr12 equations provide the same results as the nds yield limit equations.

Provides users with a web based approach to calculating capacities for single bolts nails lag screws and wood screws per the 2015 nds.

Steel plate holding a 2800 lb load to a 4 10 wood beam as shown in figure 9 25.

The wood used is spruce pine fir no 1 no 2 the loads are dead and live only so that c d 1 0 and the wood is fabricated and used dry.

Wood to wood wood to concrete and wood to steel connections are possible.

This should include checks for bearing pullover edge dis tance and other factors as required.

Screw connection failure in the steel sheet must also be checked.

Wood adjust fac tors should not be applied to the strength of the screws and the attached steel sheet when the capacity is de termined per aisi s100.

Technical report 12 yield limit equations the equations are fairly complex but it should be intuitive that the calculated fastener capacity decreases with increasing gap.

The design provisions for the shear strength of steel to steel screw connections provided by section e4 3 of the north american specification for the design of cold formed steel structural members aisi s100 12 are based on testing.

Distance between holes ensures strength of the metal and prevents holes from deforming during the bending or forming processes.

Allowable loads are based on 12 thick main members and assume no gap between side and main members.

Standard allowable loads 1 8 maximum hanger gap many of these products are approved for installation with strong drive sd connector screws.

In the shear test series screw fastened connections between two steel sheets in a single lap configuration were evaluated.

Seven different types of screws were tested.