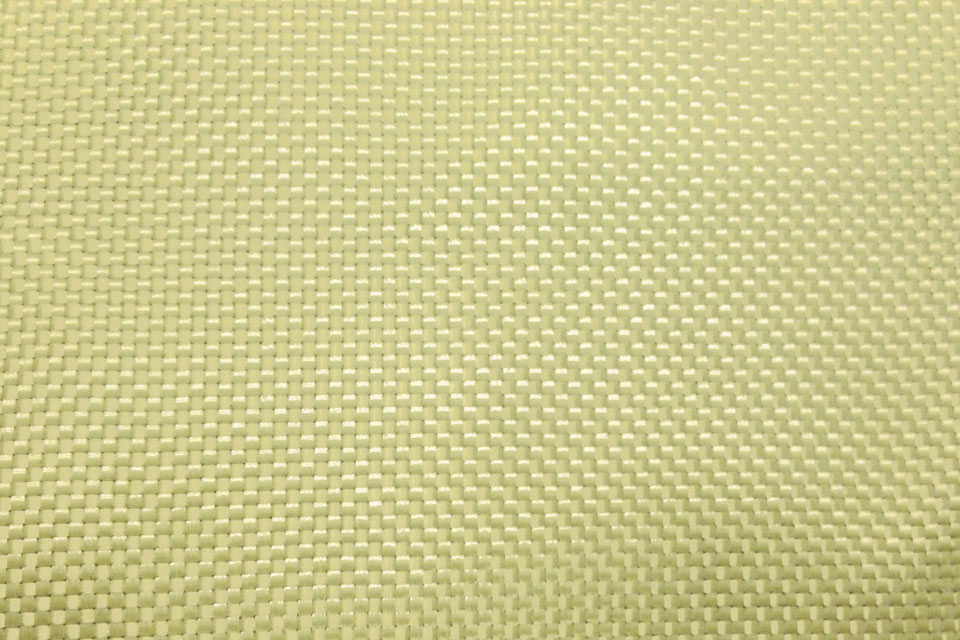

A laminate comprising aramid paper containing aramid fiber and aramid pulp and polyester film the aramid paper and polyester film having been subjected to plasma surface treatment before laminating wherein the aramid paper and polyester film are continuously bonded to each other.

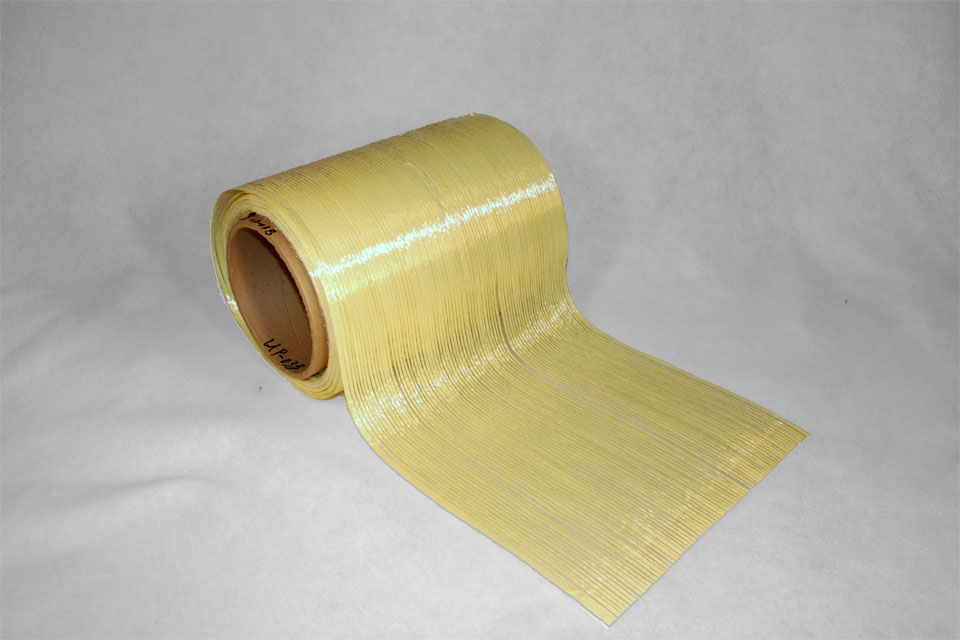

Aramid laminate roll.

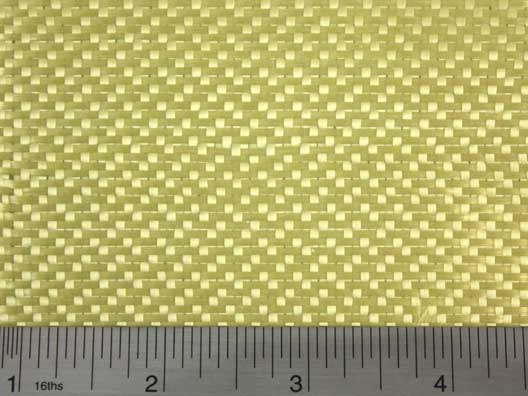

Works well as a hybrid material.

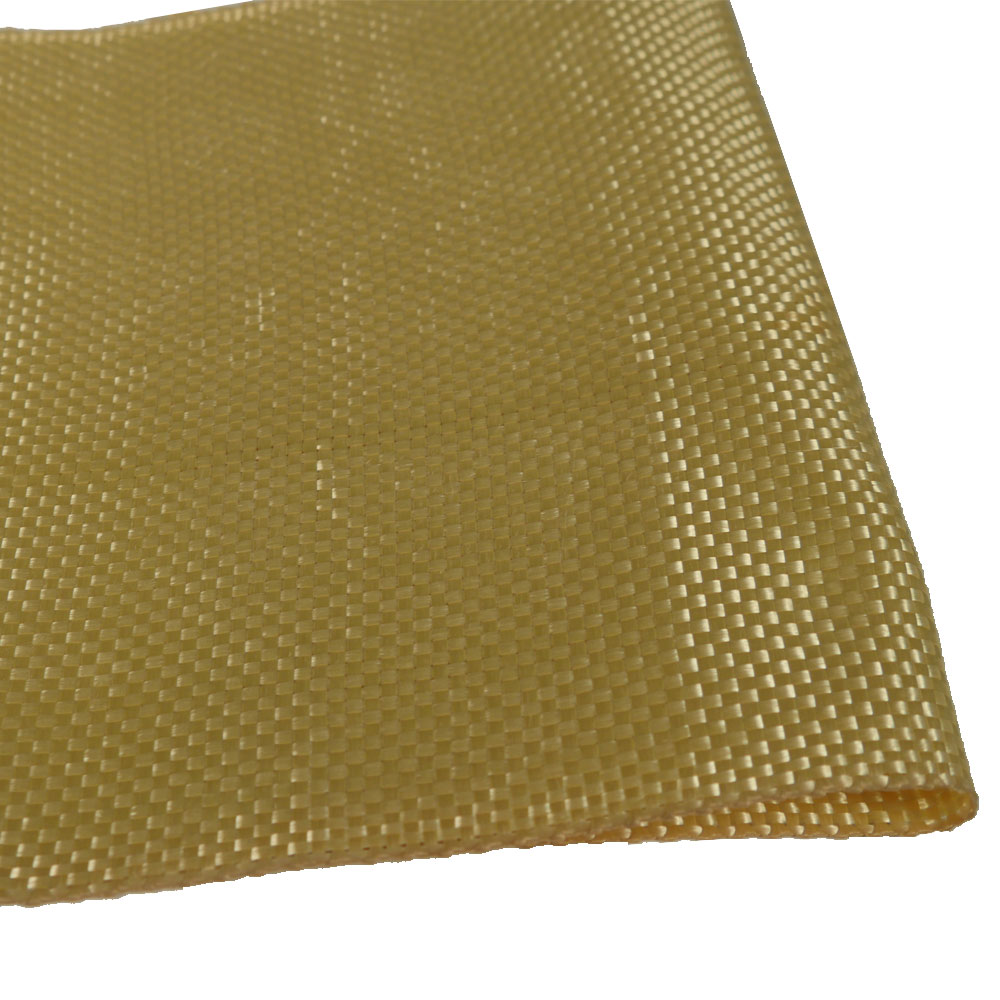

Water proof kevlar aramid fabric tpu laminate roll find complete details about water proof kevlar aramid fabric tpu laminate roll water proof kevlar aramid fabric tpu laminate roll water proof k29 kevlar aramid fabric k29 aramid tpu laminate from other fabric supplier or manufacturer jinsor tech industrial corporation.

The parameters of fisher snedecor f and the p value were calculated as 2 44 and 0.

A laminate of aramid nonwoven sheet and polyester resin having an overall thickness of 5 to 25 mils 0 13 to 6 4 mm and having an elongation at break of at least 40 in both the cross and machine direction and an average tear load in excess of 1 5 pounds force 6 7 newtons in both the cross and machine directions.

Get contact details and address id.

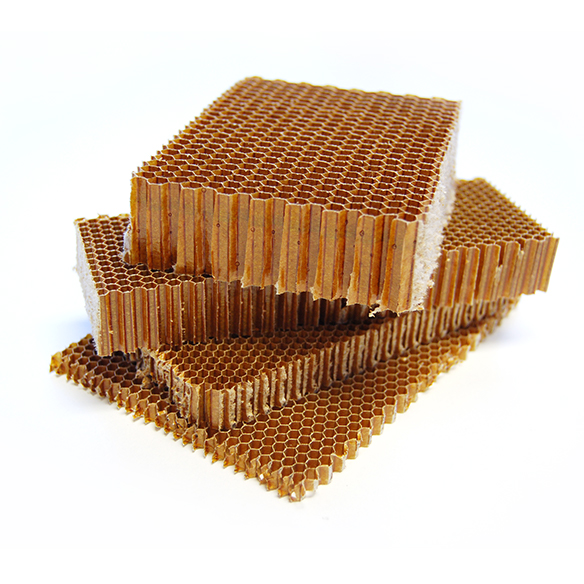

Nomex type 410 calendered available in thicknesses from 0 05mm to 0 76mm.

Aramid characterized roll method according prior art date 2007 01 31 legal status the legal status is an assumption and is not a legal conclusion.

In addition elastic rollers are also used for special uses including laminating.

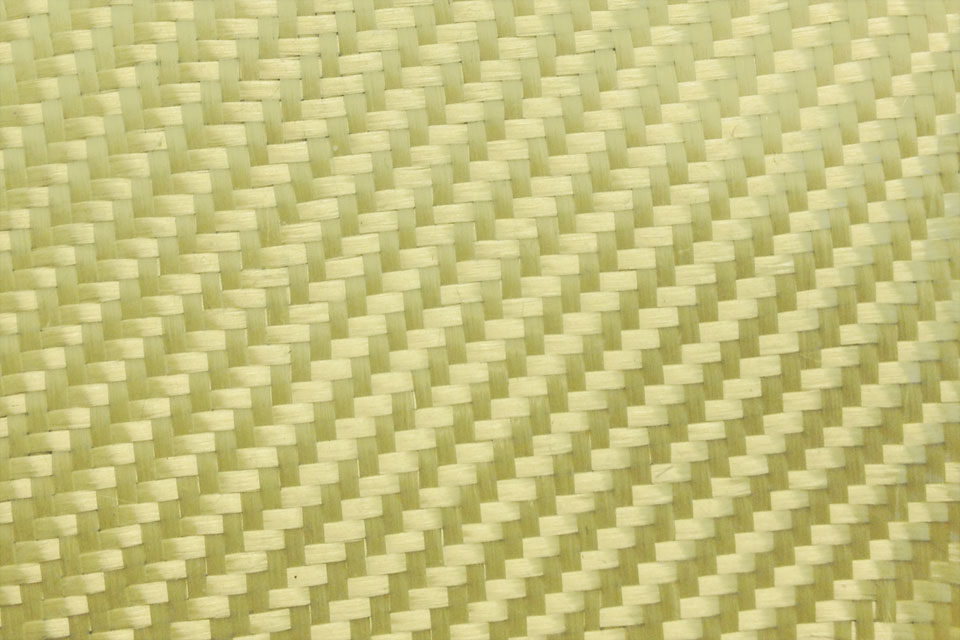

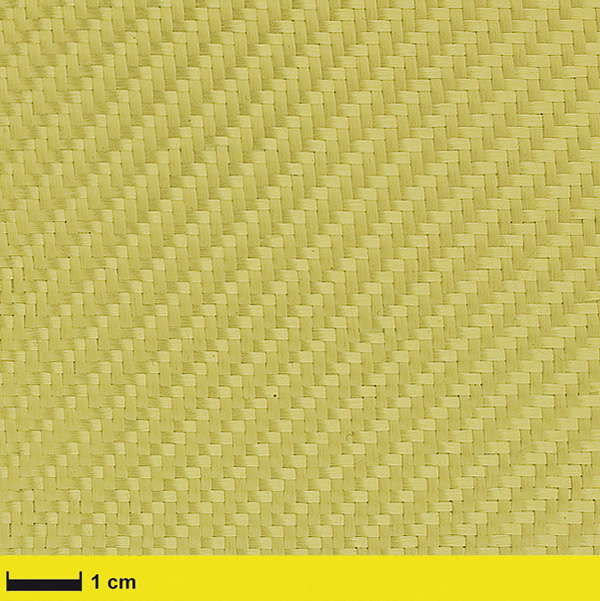

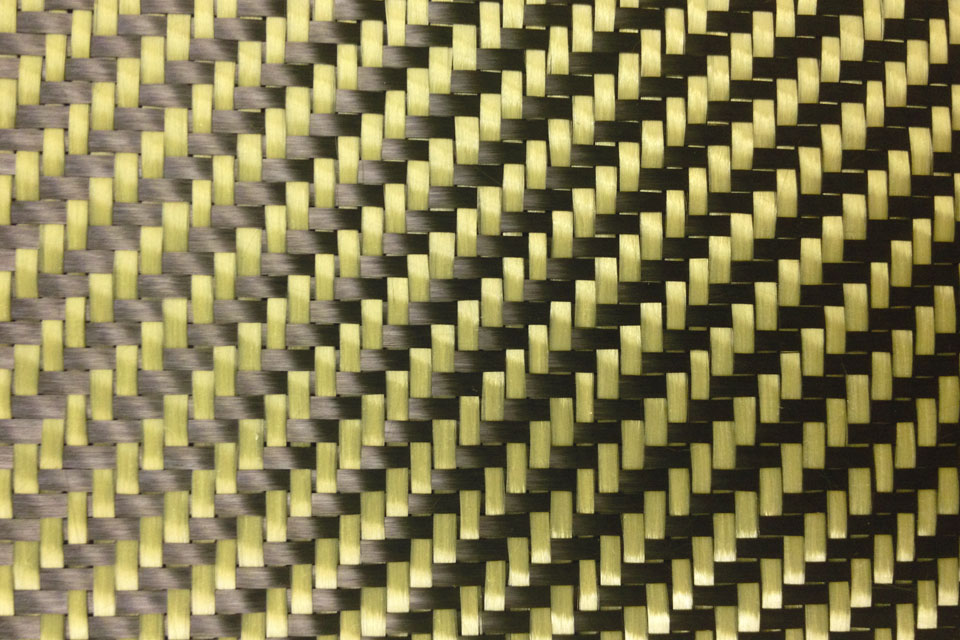

Aramid s are successfully combined with e and s glass as well as carbon fibers to enhance the laminate impact and thickness properties at the lowest possible weight.

Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.

Manufacturers have very specific needs and requirements when it comes to the fabrics and laminates they need for their production processes.

Provides the best mechanical properties and is the most widely used version.

Aramid fiber will yield prior to breaking and is very difficult to fail even with sharp impact loads.

Aramid polyester laminate.

The disclosure is concerned with a process for manufacturing the laminate and an apparatus for manufacturing the.

Often used as soft cushioning material or when conformability and impregnability are of importance.

Main uses of them are for embossing to make uneven structure on material surface and for calendering to make glossy and flatness.

Nomex type 411 uncalendered available in thicknesses from 0 13mm to 0 58mm.

As materials for elastic rollers aramid fibers which have resistances from heat and pressure are used.

Harnawa inc offering harnawa off white laminated aramid paper apa packaging type.

A statistical analysis of variance anova was performed to the data.

The mas with ramie fabric composite and aramid laminate both studied by monteiro et al.